Industrial dumping carts are a saving grace in the machine tool industry. Not only can they make waste management safer, the right system can reduce your production down time! In order for your business to get the most out of any tool, some research is recommended. Here are a few tips for finding the best Dumping CART for you! We call this the CART method:

- (C)apacity

- (A)ccessssibility

- (R)ules

- (T)ime savings

CAPACITY:

The frequency you will be dumping the carts is determined by the following variables:

- Determine the max lip height for the cart (must fit under the machine tool conveyor).

- Determine the volume of chips each of your machines is producing per shift.

- Determine the max capacity of the cart based on the max lip height and cart dimensions.

Bigger does not always mean more volume. While a self-dumping hopper’s size may be alluring, there is a lot of wasted space in its design. This contributes to its large footprint, and may potentially congest your workspace. There are alternatives that boast equal or more volume capacity, more mobility and a much smaller footprint.

ACCESSIBILITY

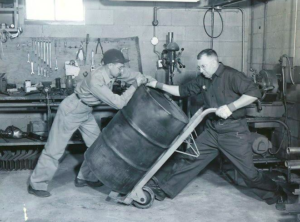

If this picture looks familiar, you might have an accessibility problem. A few of the questions to ask your team when determining accessibility constraints are:

- How congested is the space around the machine tool?

- Can the cart be easily maneuvered into position under the conveyor?

- Can you move the cart without a fork truck?

- What distance will your cart have to travel to be dumped?

- How much space is in the aisles relative to the cart or fork truck?

RULES

Review the cart for company rules regarding safety, maneuverability & flexibility.

- Can the cart be moved easily & safely in tight spaces?

- Can the cart be dumped easily & safely?

- Can the cart be moved by one person?

- Will cart positioning prevent chips from falling on the floor?

- Will the cart leak metalworking fluid on to the floor?

- Can you maneuver the cart from more than one side?

- What is the best Dumping method for you?

TIME:

Time is of the utmost importance in our industry. Mobile industrial carts are the right tool for managing machine tool waste:

- Can you quickly transport the cart from the machine tool to the dumping area?

- Will the cart need a fork truck or pallet jack to move the cart away from the machine tool?

- How quickly can you safely change out a cart?

- What is the cost of lost productivity when a cart needs to be emptied?

There are many considerations when determining the best dumping cart option for your shop. Consider speaking with your dumping cart professional about how you can save time & money with the right tool and the right processes for dumping your machine tool chips. If you want more information about CECOR carts please contact us.