The CECOR staff has visited with many companies regarding their metal working fluid over the years because of the equipment we manufacture. Through industry observation, visiting with people in the metal working industry and Metal Working Fluid manufacturers themselves we have much about metal working fluid. While we don’t pretend to be an authority on any one companies metal working fluid operation, we do understand the need for maintaining tools in the machining industry through good preventive maintenance practices.

We would like to start by classifying metal working fluid as a TOOL and not just a fluid. Most expensive tools in your shop need some sort of preventive maintenance. Like these other tools in your shop, your metal working fluid requires preventive maintenance to maximize its ability to keep your production costs low.

The greatest value of your metal working fluid is to increase the efficiency of your machine tools and allow you to produce more products at a lower cost. To do this your metal working fluid needs to perform 2 or 3 basic tasks at the cutting surface:

- Lubrication – prevent heat

- Cooling – remove heat

- Removal of chips or other debris from the cutting surface

The above tasks will not be done efficiently over time unless you keep the metal working fluid within the manufactures recommended standards. This can be accomplished through a set of simple tasks we refer to as a preventive maintenance or a housekeeping program.

What is a Housekeeping Program

In short, a housekeeping program is designed to keep your metal working fluid within the manufactures specs at all times. When metal working fluid is tested and the results are recorded and reviewed on a routine basis you will be able to see when your fluid in each machine tool begins to move towards the outer edges of the manufactures desired parameters.

Many shops treat their metal working fluid more like a fluid than a tool. When it is time to top off the coolant tank with 5 gallons of metal working fluid they will either:

- add water or

- add concentrate or

- add a predefined mix

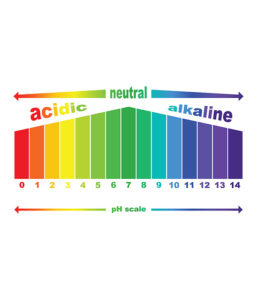

irregardless of the current concentration. A housekeeping program will give you the knowledge of both the history and the current results of a variety of tests that have been done on a specific machine tool. This way you can take into account the pH, concentration, amount of tramp oil, amount of sludge and potentially other factors to determine the best next move for the machine’s metal working fluid. We will address additional thoughts in future newsletters &/or blogs. We do recommend you visit with your metal working fluid Manufacturers Representative and/or your metal working fluid manufacturers lab and ask what test(s) are important and the required frequency of the tests to keep your fluid within the manufactures specifications. Depending on the metal working fluid and variables in your shop, the tests & frequency of tests may be different.

Housekeeping Program Value Proposition

- Adding to tool life

- Reduce health & safety issues

- Less rejects or rework

- Limiting unplanned down time

- Expanding recycling options

- Warn you about potential problems with your metal working fluid before they become critical

- Extend the quality life of metal working fluid

Just like checking/changing the oil in your vehicle, you need to do a few routine tests on the status of your metal working fluid and adjust it as necessary. When your metal working fluid loses its ability to perform lubrication and/or cooling efficiently, your production costs will go up. Unfortunately, without the data from a housekeeping program, you may not know it until after the additional costs have been incurred. You may never know because, over time, it becomes normalized and the additional costs are just part of your overall production costs. Here are a few tell-tale signs that your metal working fluid may be having problems:

- Poor cutting tool life

- Out of spec finished parts

- More rework required

- Health & safety issues – Dermatitis

- Odor from the sump – Bacteria or mold growth

- Foaming

A few tests to consider

We recently had an interesting conversation with a metal working fluid manufacturer in which they estimated that about 80 percent of the issues with water-based metal working fluids are created because the metal working fluid was outside of one or more the following manufacturers recommended parameters:

- Concentration & pH

- Amount of Tramp oil in fluid

- Machine cleanings

- Volume of fluid in machine coolant tank

The metal working fluid manufactures have said that with a formalized housekeeping program, you can increase the quality life of your metal working fluid and reduce, or eliminate, the risks of it being a contributing factor to the potential problems stated earlier.

A metal working fluid housekeeping program will allow your company to develop synergies by associating a set of specific processes with your metal working fluid usage. Hopefully we have demonstrated some potential cost saving ideas & goals for you to achieve by developing and implementing your own metal working fluid housekeeping program.