Why Use Sump Sharks with your Coolant Recycling System?

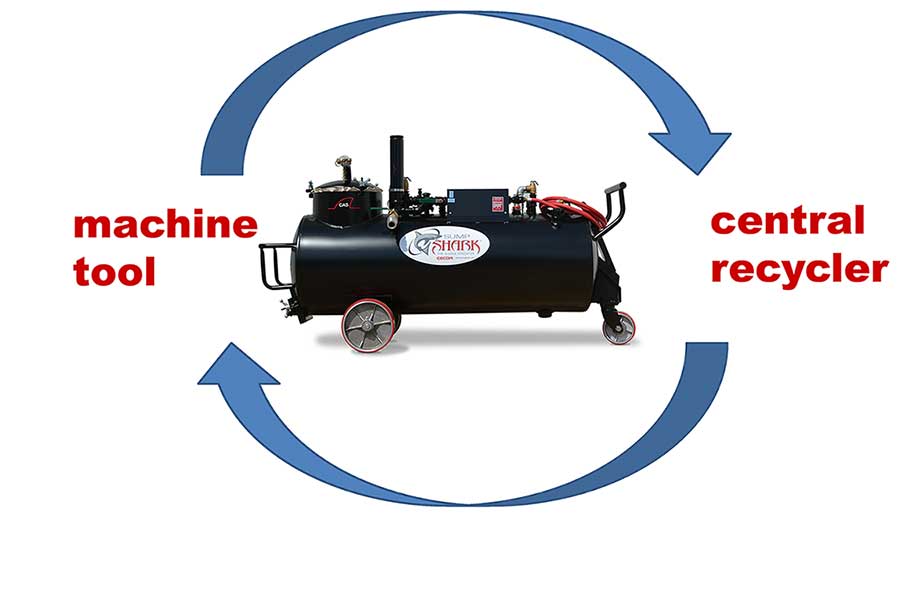

Our Combination Sump Sharks are designed to work in tandem with a central recycler or coalescer. A CECOR sump cleaner/coolant dispenser consists of two separate tanks on a single chassis. One tank is a sump cleaner. The other tank is a dispenser. Most often utilized as part of a central machine coolant recycling program, these two-tank coolant recycling systems units are the most efficient way to address your coolant cleaning requirements.

How Optimal Coolant Recycling Functions are Performed by Each Tank

The Sump Cleaner Side

The side with the filter is the sump cleaner side. This side is also called the dirty pick-up tank because it is where the dirty metalworking fluid and sludge goes when it is vacuumed from the machine tool. A vacuum pump creates a vacuum in the sump cleaner tank.

The sump cleaner or dirty pick up tank side has two functions:

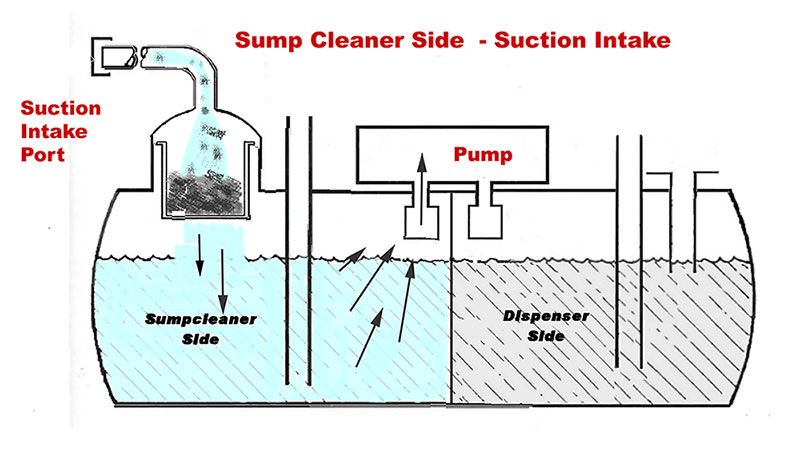

- Clean machine tool sumps. The vacuum sucks in dirty metalworking fluid and sludge through the hose into the top of the tank where it passes through a filter. The filter catches solids and performs CNC coolant cleaning function. Filtered fluid then flows into the tank.

- Pumps then move filtered coolant out of the sump cleaner tank. The filtered coolant can be pumped back through the discharge into the machine tool, transported to a central recycling system or to the fluid waste area of the plant.

The Dispenser Side

The side without the filter is the dispenser side. It is also called the clean delivery tank. This tank dispenses fresh or recycled coolant to the machine tool. It can be filled using the onboard pump or through the fill hatch.

The dispenser or clean delivery tank side has two functions:

- Carry fresh coolant or recycled coolant from a recycler to the machine tool.

- Dispense coolant. Coolant is pumped out through the clean tank dispenser hose.

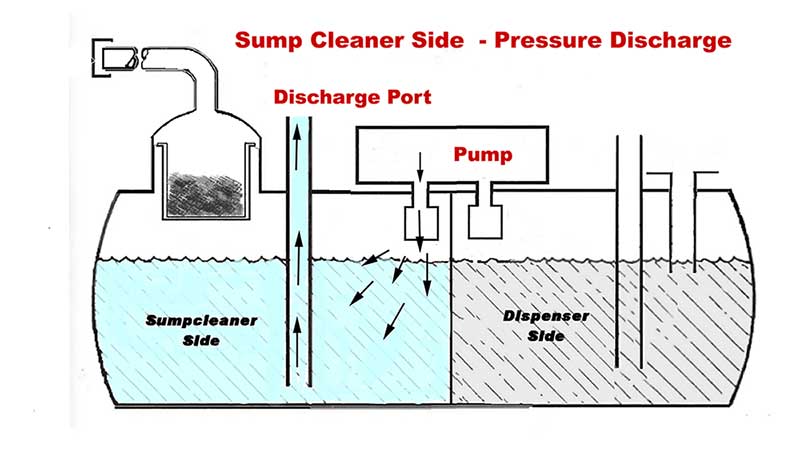

Sump Cleaner Side Diagram

A vacuum pump creates a vacuum in the sump cleaner tank. The vacuum pulls in the contents. As fluid and solids flow through the hose into the suction intake port, the solids are caught in the filter which completes the coolant recycling process. The clean fluid then continues into the tank.

When pump is switched to discharge, a low pressure develops in the tank that forces the filtered fluid up through the discharge port.

When pump is switched to discharge, a low pressure develops in the tank that forces the filtered fluid up through the discharge port.

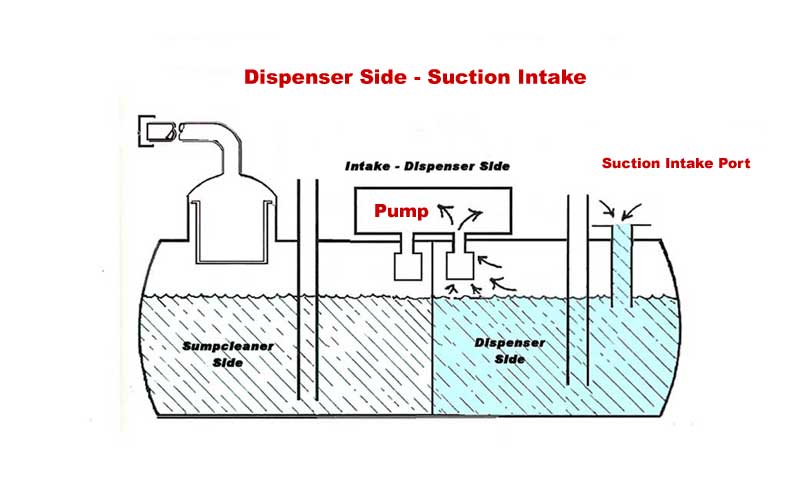

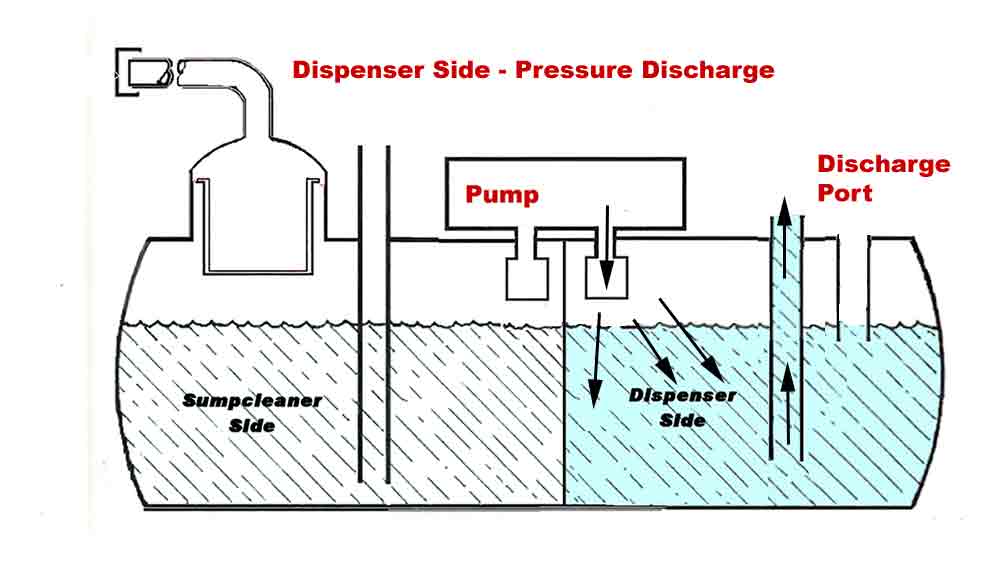

Dispenser Side Diagram

When pump is switched to discharge, a low pressure develops in the tank that forces the filtered fluid up through the discharge port.

Fill with fresh coolant or from coolant recycler

Fill with fresh coolant or from coolant recycler

A vacuum pump creates a vacuum in the dispenser or clean tank. The vacuum pulls in new coolant or coolant from central recycler for transporting to machine tool. The dispenser side can also be filled through the fill hatch at the top of the tank. When the pump is switched to discharge, a low pressure develops in the tank that forces the filtered fluid up through the discharge port.

Role in Coolant Recycling Systems

CECOR Combination Sump Shark/Dispenser units work well with coolant recycling systems by filtering chips and sludge from coolant prior to transporting to central coolant recycler. Use the dispenser side to transport treated coolant back to machine tool sump.